Discover the Great Discounts on Industrial Coffee Grinder Options Now

Discover the Great Discounts on Industrial Coffee Grinder Options Now

Blog Article

Industrial Coffee Grinder Overview: Boost Effectiveness and Top Quality

In the affordable landscape of coffee manufacturing, picking the appropriate commercial coffee mill plays a critical function in improving both performance and item top quality. Recognizing the subtleties of numerous grinder types and key features-- such as personalized work setups and robust building-- can considerably influence the last taste profile of the coffee.

Understanding Mill Kinds

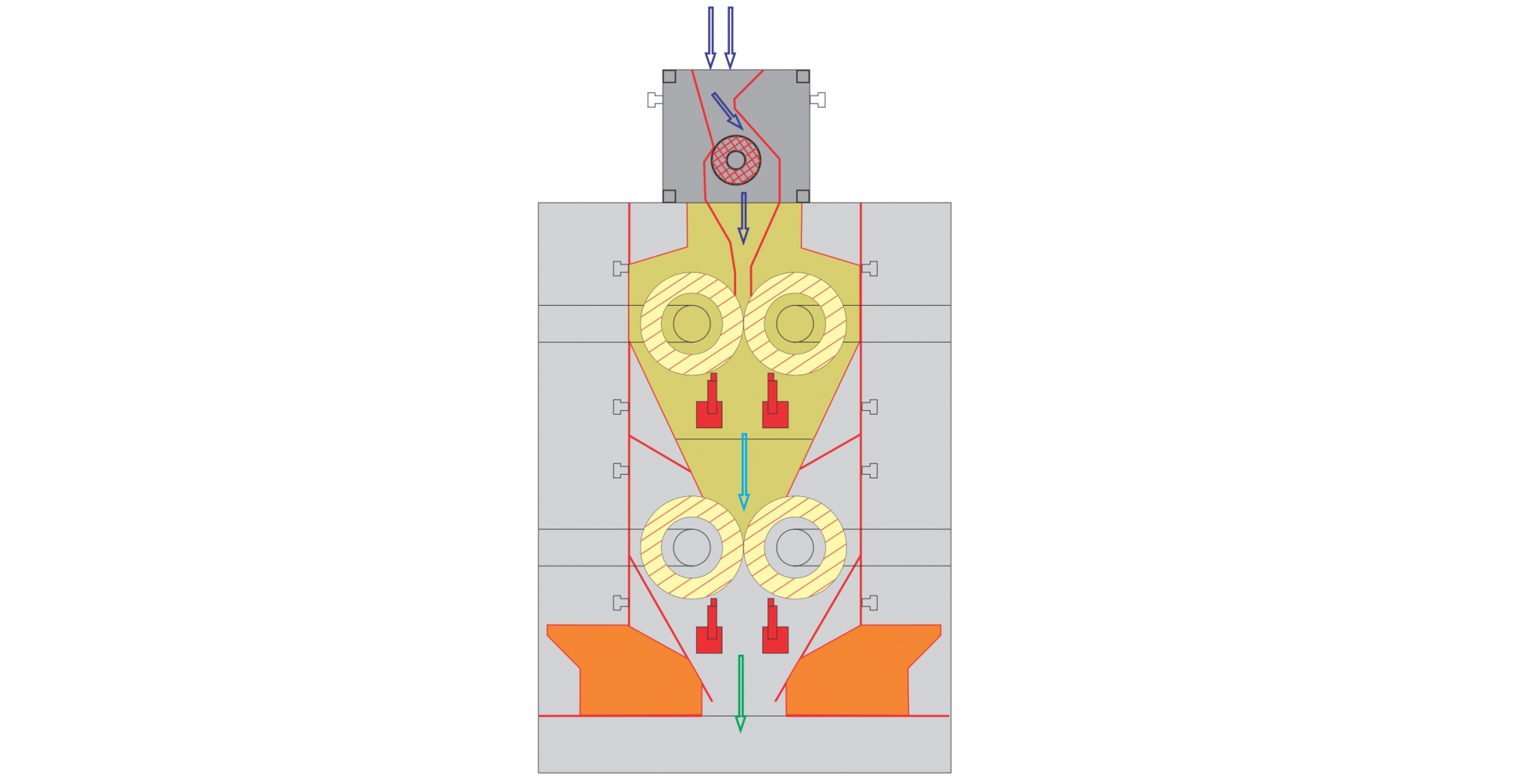

When choosing an industrial coffee grinder, comprehending the various kinds readily available is vital for enhancing both flavor removal and functional effectiveness. Both primary kinds of mills are blade grinders and burr mills. Blade mills use sharp blades that chop coffee beans right into inconsistent dimensions, bring about unequal extraction and possibly unfavorable flavors. While blade mills are commonly much more appropriate and economical for small operations, they are generally not suggested for industrial usage.

Ultimately, picking the best kind of grinder is important to preserving top quality and effectiveness in coffee manufacturing, making it necessary for companies to purchase top quality burr mills for optimum results.

Secret Features to Consider

Choosing a commercial coffee mill requires cautious factor to consider of several essential attributes that can significantly influence both efficiency and the overall coffee experience. One of the main facets to evaluate is the grinding mechanism. Burr mills are typically liked over blade mills, as they give a regular work dimension, which is crucial for ideal extraction and flavor.

Another essential attribute is the mill's capability. A flexible grinder with multiple setups permits you to customize the grind size to different developing approaches, improving the coffee's flavor profile.

The building material additionally plays a duty in durability and maintenance. Stainless-steel parts commonly provide longevity and are easier to cleanse, which is necessary for preserving hygiene criteria. Finally, assess the grinder's sound degree, especially in an active coffee shop or manufacturing environment, where too much sound can be disruptive. Investing in a mill that balances these features can substantially improve both functional effectiveness and the top quality of the coffee served.

Optimizing Grinding Process

To accomplish the most effective cause coffee prep work, maximizing the grinding procedure is vital. The grind dimension considerably affects extraction, taste, and overall high quality of the made coffee. Different brewing techniques require details grind dimensions; as an example, more info here espresso demands a great work, while French press necessitates a crude texture. Comprehending the relationship in between grind dimension and brewing approach is the very first step in optimization.

In addition, monitoring the grinding speed can optimize the process. Slower grinding often produces less heat, preserving fragile tastes and fragrances. Alternatively, much faster grinding might produce extreme warm, negatively impacting this website the coffee's quality.

Maintenance and Care Tips

Proper upkeep and treatment of industrial coffee grinders are essential for guaranteeing optimal efficiency and long life. Normal cleansing is the structure of maintenance; residue build-up can influence taste and grinding effectiveness. It is a good idea to clean the grinder after each usage, wiping down the exterior and eliminating any kind of coffee premises from the burrs.

Furthermore, check the grinding burrs for deterioration. Dull burrs can compromise work consistency, so they should be changed as needed. Industrial Coffee Grinder. Regularly calibrating the grinder is likewise important, as this preserves the wanted grind size for numerous brewing approaches

Lubrication of relocating parts must be carried out according to the supplier's specs, as this reduces rubbing and prolongs the life of the tools. It is necessary article to use food-grade lubricating substances to make sure safety and compliance with wellness guidelines.

Last but not least, keep the mill in a dry and secure environment to stop rust and rust. By sticking to these maintenance and treatment tips, drivers can boost the efficiency of their commercial coffee mills while guaranteeing high-quality outcome and extended functional life.

Roi Evaluation

Reviewing the roi (ROI) for industrial coffee grinders is important for organizations looking for to maximize their coffee production capabilities. A complete ROI evaluation aids determine the financial practicality of purchasing high-grade grinders, allowing businesses to weigh the initial expenses against potential gains.

Evaluate the acquisition rate of the mill, consisting of setup and any type of needed adjustments to existing framework. High-performance mills commonly lead to minimized grinding time and enhanced throughput, which can dramatically improve performance.

In addition, take into consideration the effect on product top quality. Industrial Coffee Grinder. Superior mills generate an even more constant work dimension, which can boost flavor profiles and consumer satisfaction, eventually driving sales. By enhancing the quality of the end product, businesses can validate higher pricing, leading to boosted revenue

Verdict

In summary, an industrial coffee grinder plays a crucial function in boosting both performance and item quality within coffee production. Inevitably, the tactical financial investment in a trustworthy grinder contributes substantially to boosted income and competition in the coffee industry.

In the affordable landscape of coffee manufacturing, picking the right industrial coffee mill plays a critical role in boosting both performance and product quality. The two primary kinds of grinders are blade grinders and burr mills. Within the burr mill group, there are flat burr grinders and conelike burr mills, each with its benefits. Burr mills are typically favored over blade mills, as they offer a constant grind dimension, which is critical for ideal removal and flavor.

In summary, a commercial coffee mill plays an essential duty in improving both performance and product top quality within coffee production.

Report this page